§1. How to wire AC Rectification Solid State Relay

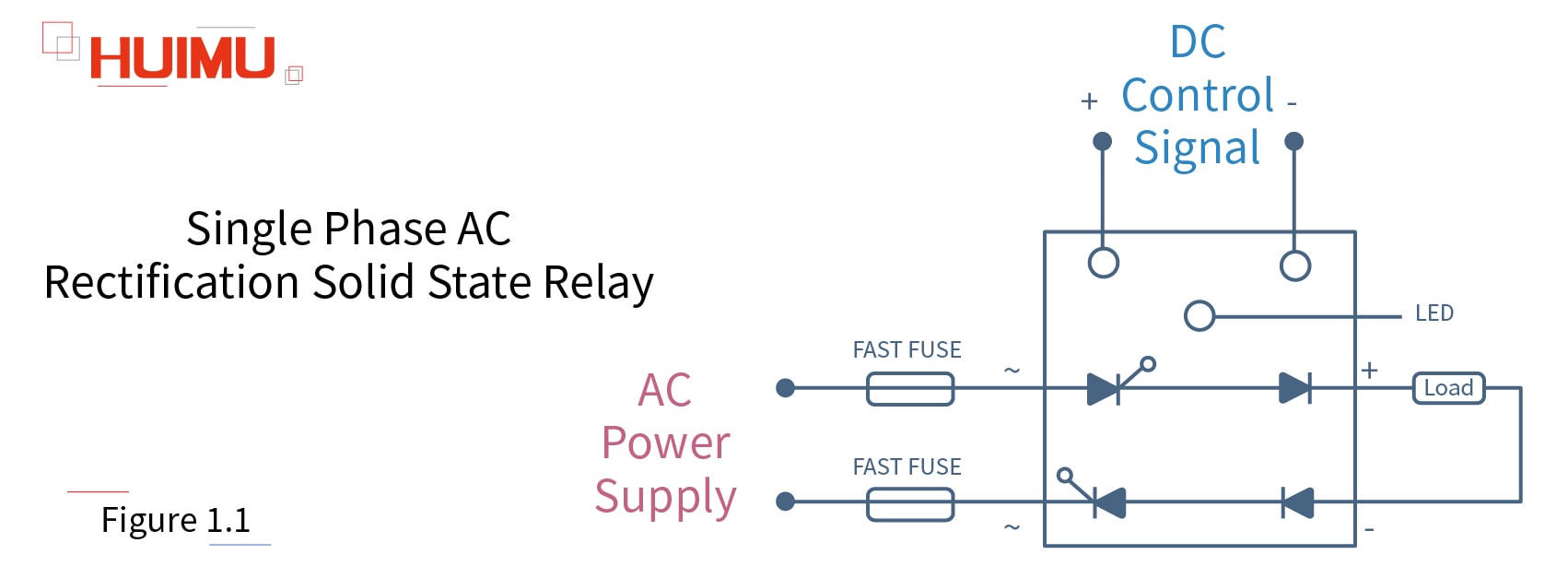

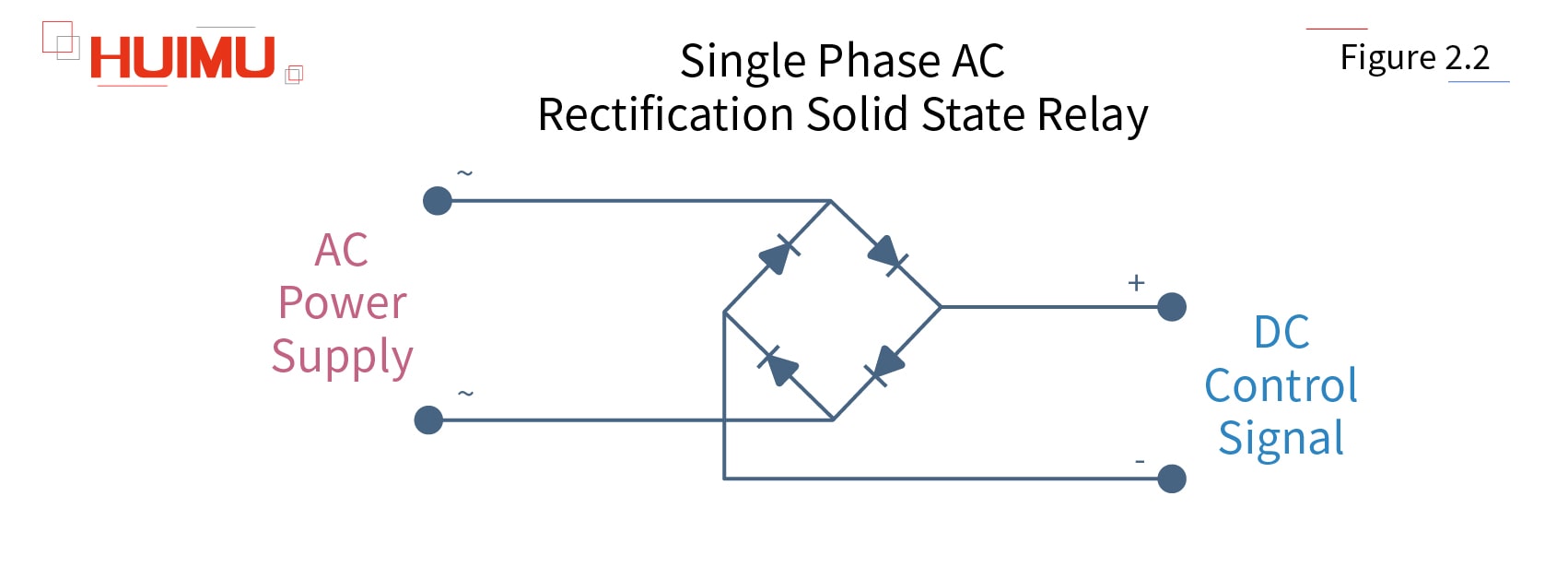

1.1 Single Phase AC Rectification Solid State Relay

MGR-ZK Series

The single phase ac rectification solid state relay has six terminals, which can be used to the industrial and commercial applications. The input circuit is connected to the DC control signal device, and the output circuit is connected to the AC power source and the DC load.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the rectification solid state relay meet the requirements of the application.

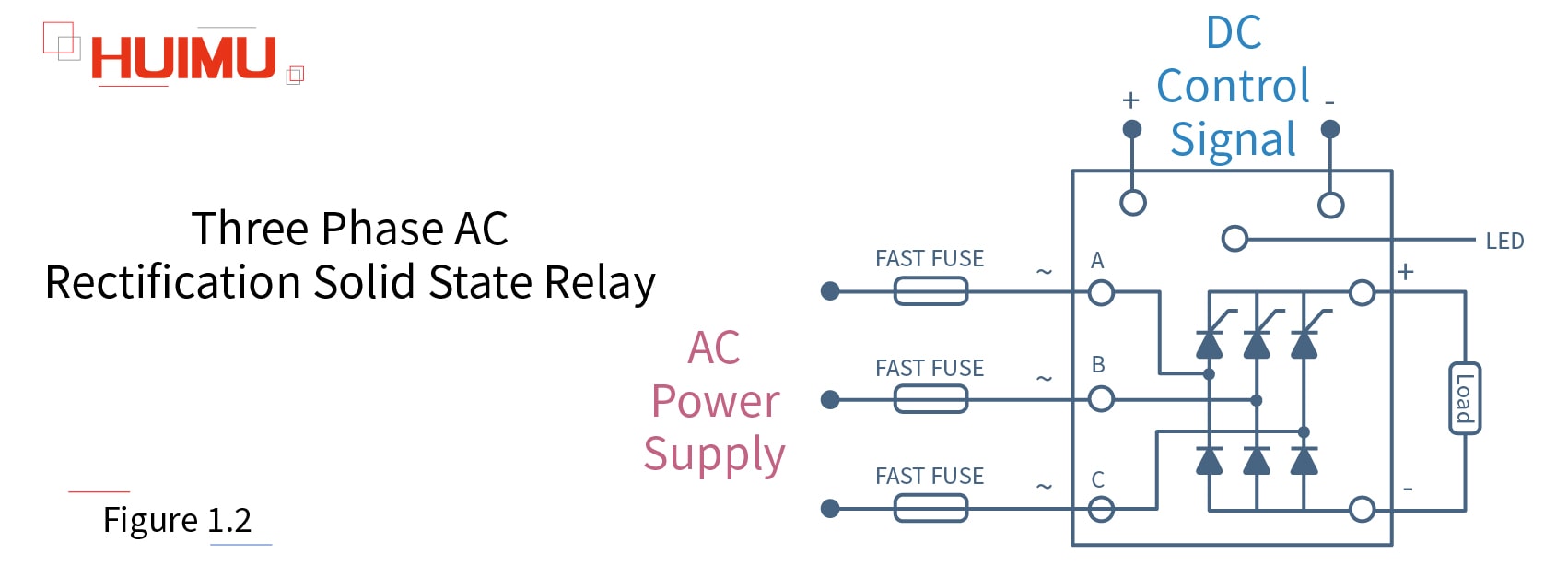

1.2 Three Phase AC Rectification Solid State Relay

MGR-3ZK Series

The three phase ac rectification solid state relay has seven terminals, which can be used to the industrial and commercial applications. The input circuit is connected to the DC control signal device, and the output circuit is connected to the AC power source and the DC load.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the rectification solid state relay meet the requirements of the application.

§2. How to wire Rectifier or Rectification Module

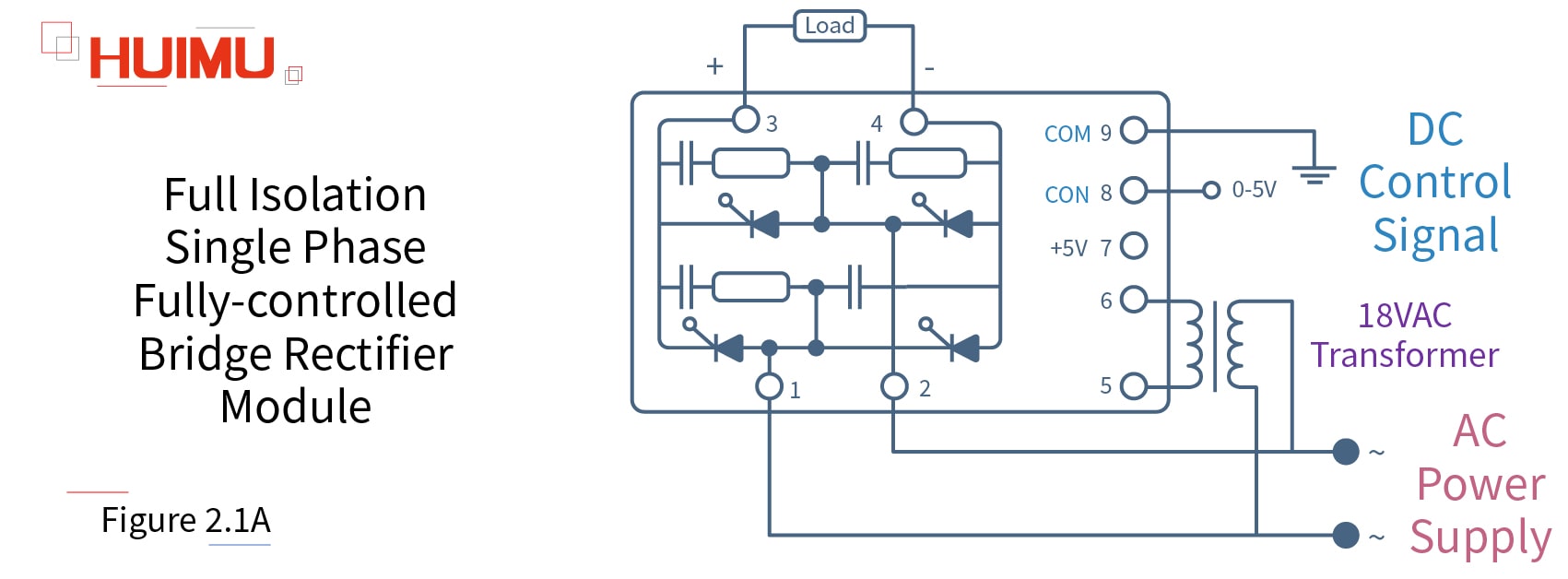

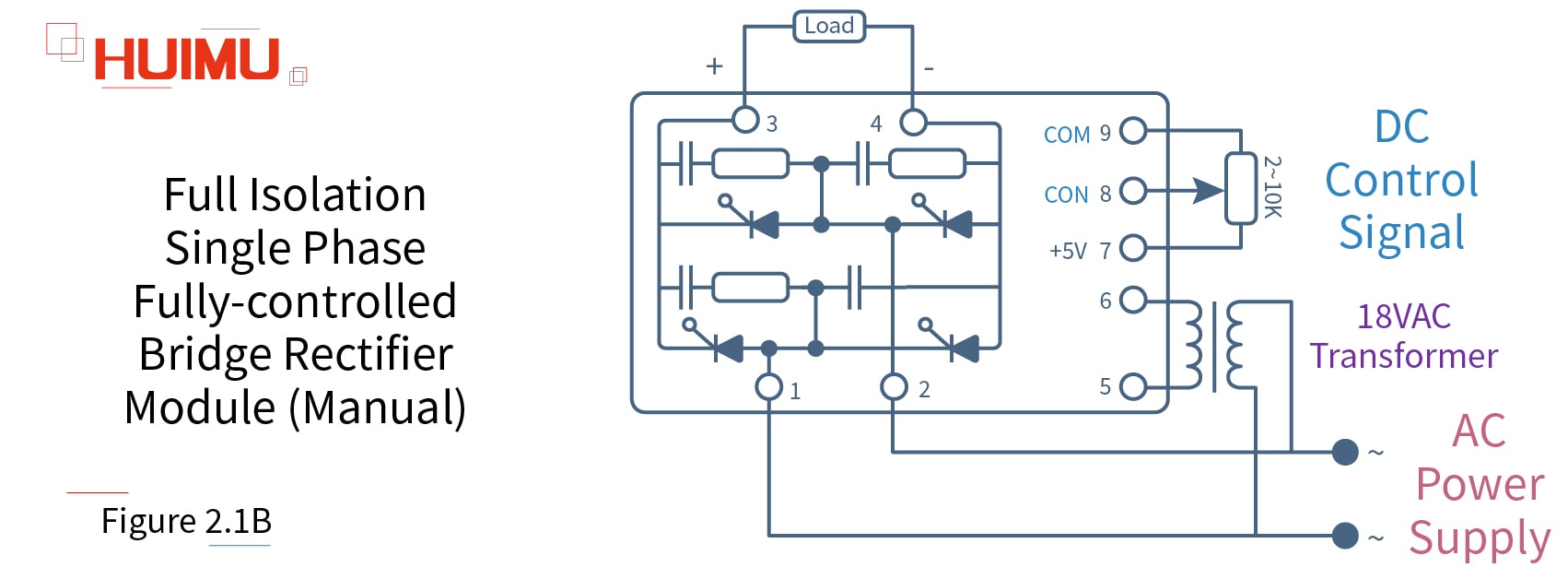

2.1 Full Isolation Single Phase Fully-Controlled Bridge Rectifier Module

MGR-DQZ Series

The full isolation single phase fully-controlled bridge rectifier module has nine terminals, which can be used to the industrial and commercial applications. Port1 and Port2 are connected to the single phase AC power supply; Port3 and Port4 are connected to the DC load; Port5 and Port6 are connected to the 18VAC external transformer, which can produce the stable synchronous voltage source; Port7 is the +5VDC generated by the module itself ; Port8 is CON, which is connected to the control signal device; Port9 is COM, which is connected to the common terminal. The control signal can be divided into automatic control signal (E type: 0~5VDC, F type: 0~10VDC, H type: 1~5VDC, G type: 4~20mA) and manual control signal (potentiometer).

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the rectifier module meet the requirements of the application.

Figure 2.1A: Automatic control signal

Figure 2.1B: Manual control signal, E, F, H types can be controlled by manual, and G type cannot

2.2 Bridge Rectifier

KBPC, QL, SQL Series

The single phase / three phase bridge rectification module uses "vacuum + hydrogenation protection" welding technology. The input circuit is connected to the AC current/voltage, or AC signal, and the output circuit is connected to the DC current/voltage, or DC signal. This rectification module is the suitable for the application, such as rectifier power supply, industrial automation control system, CNC machine, remote control system and etc.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the power diode bridge rectifier meet the requirements of the application.

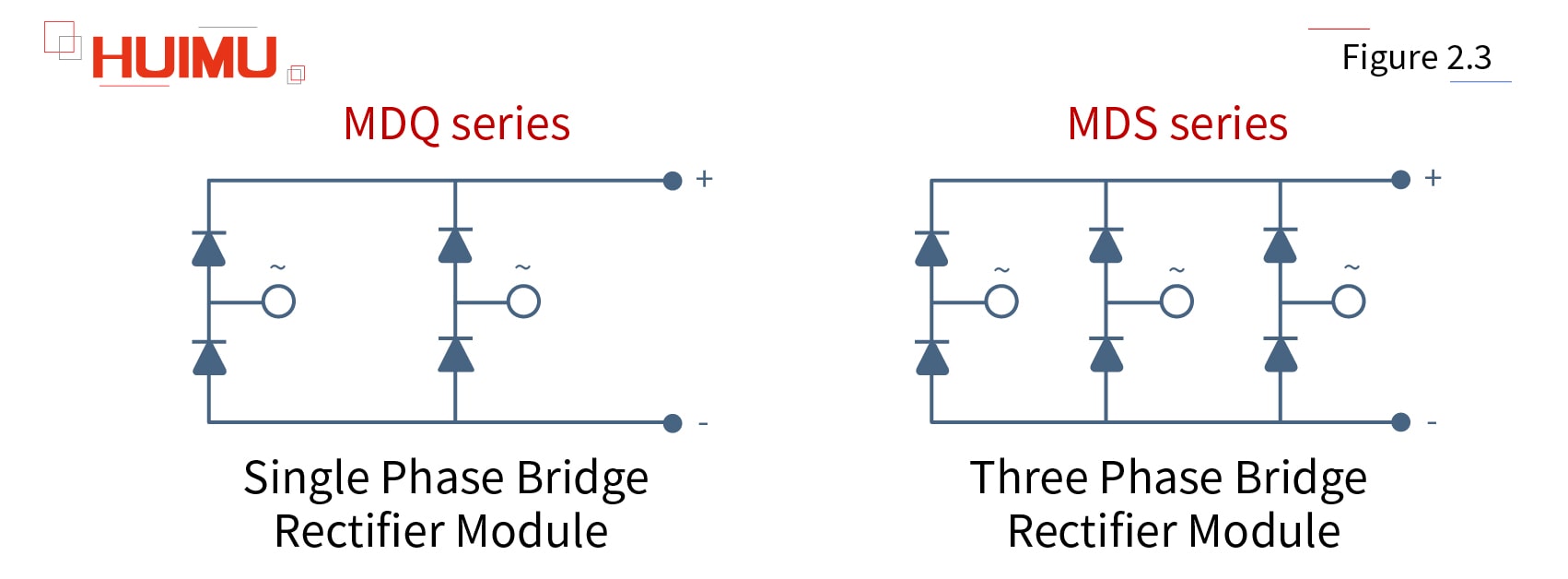

2.3 Single Phase / Three Phase Bridge Rectifier Module

MDQ, MDS Series

The single phase / three phase bridge rectification module uses "vacuum + hydrogenation protection" welding technology. The input circuit is connected to the AC current/voltage, or AC signal, and the output circuit is connected to the DC current/voltage, or DC signal. This rectification module is the suitable for the application, such as DC power supply of the instruments and equipment, Input rectification power supply of the PWM inverter, Excitation power supply of the DC motor, Input rectification system of switching power supply, Soft start capacitor charging system, Electrical drive and auxiliary current, Inverter welder, DC power charging system and etc.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the rectifier module meet the requirements of the application.

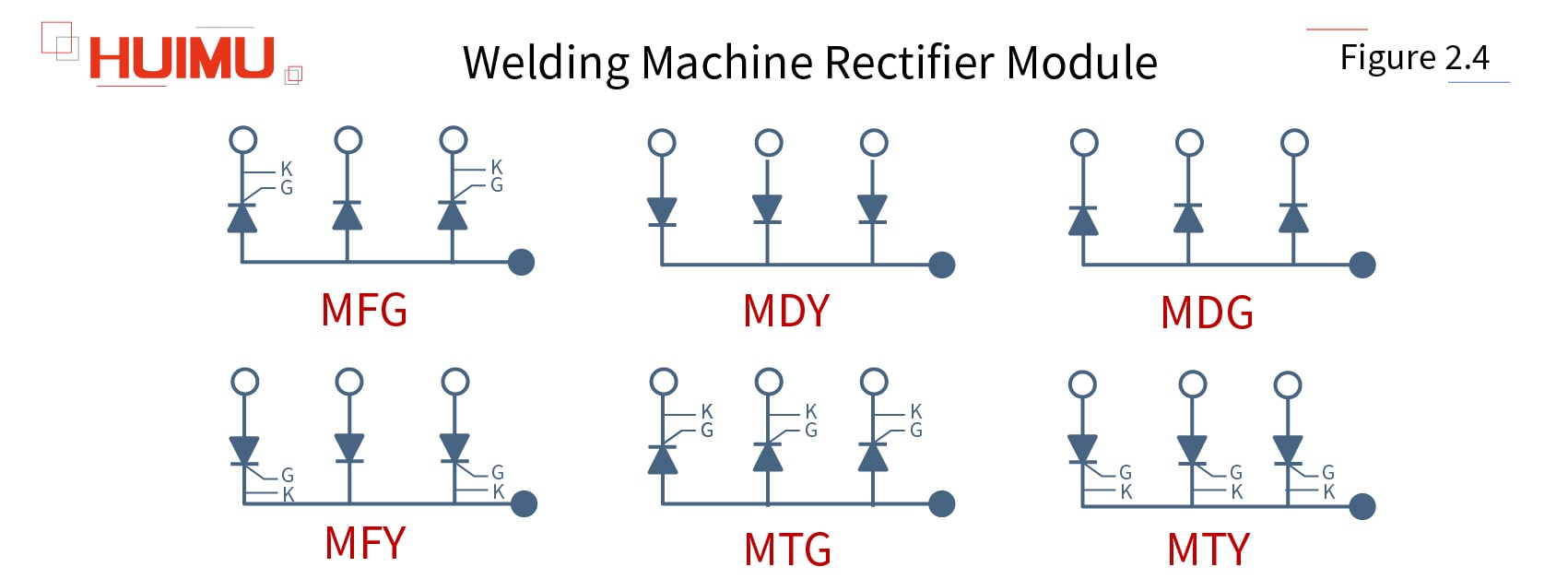

2.4 Welding Machine Rectifier Module

MT, MF, MD Series

The welding machine rectifier module uses "vacuum + hydrogenation protection" welding technology. The input circuit is connected to the AC current/voltage, or AC signal, and the output circuit is connected to the DC current/voltage, or DC signal. This rectification module is the suitable for the application, such as welding machine power supply, various dc power supplies, frequency converter and etc.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the rectifier module meet the requirements of the application.

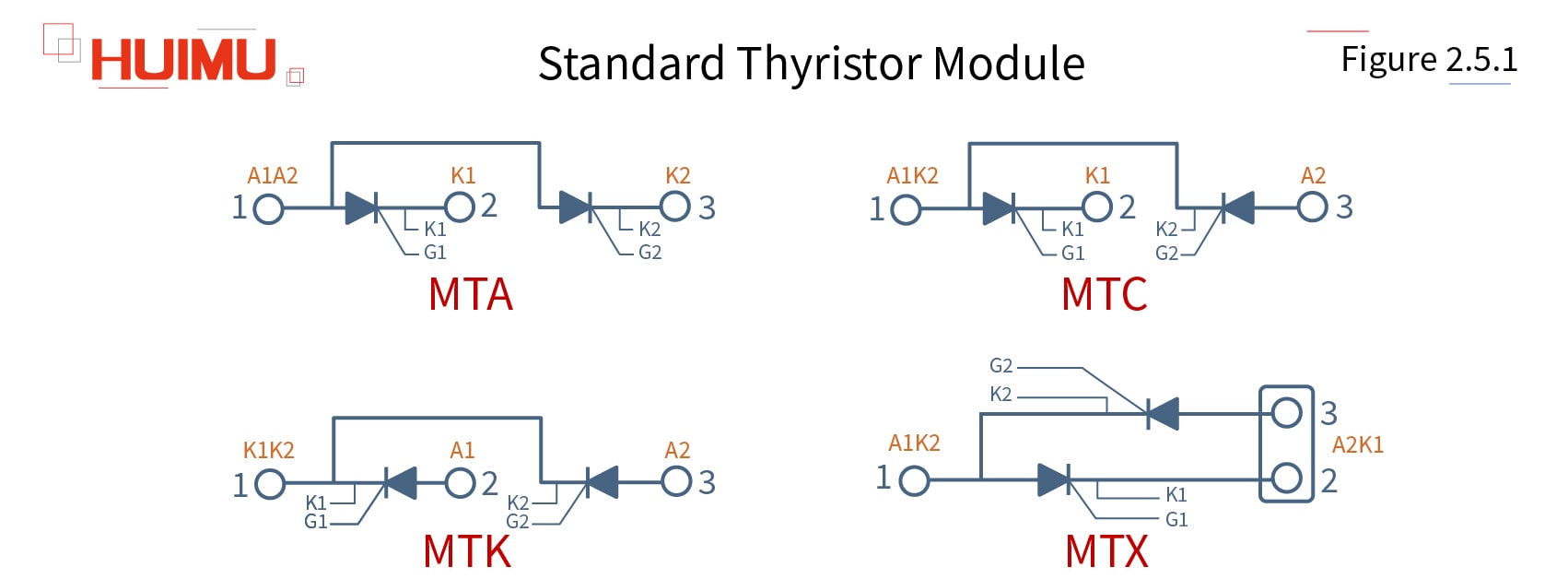

2.5 Thyristor Rectifier Module

2.5.1) Thyristor Rectifier Module

MTC, MTA, MTK, MTX Series

The standard thyristor module uses "vacuum + hydrogenation protection" welding technology, which is suitable for the application, such as control system of ac and dc motor, various rectification power supplies, industrial heating control system, lighting system, contactless switch, motor soft start, static var compensator, welding machine, frequency converter, ups power supply, battery charging and discharging and etc.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the thyristor module meet the requirements of the application.

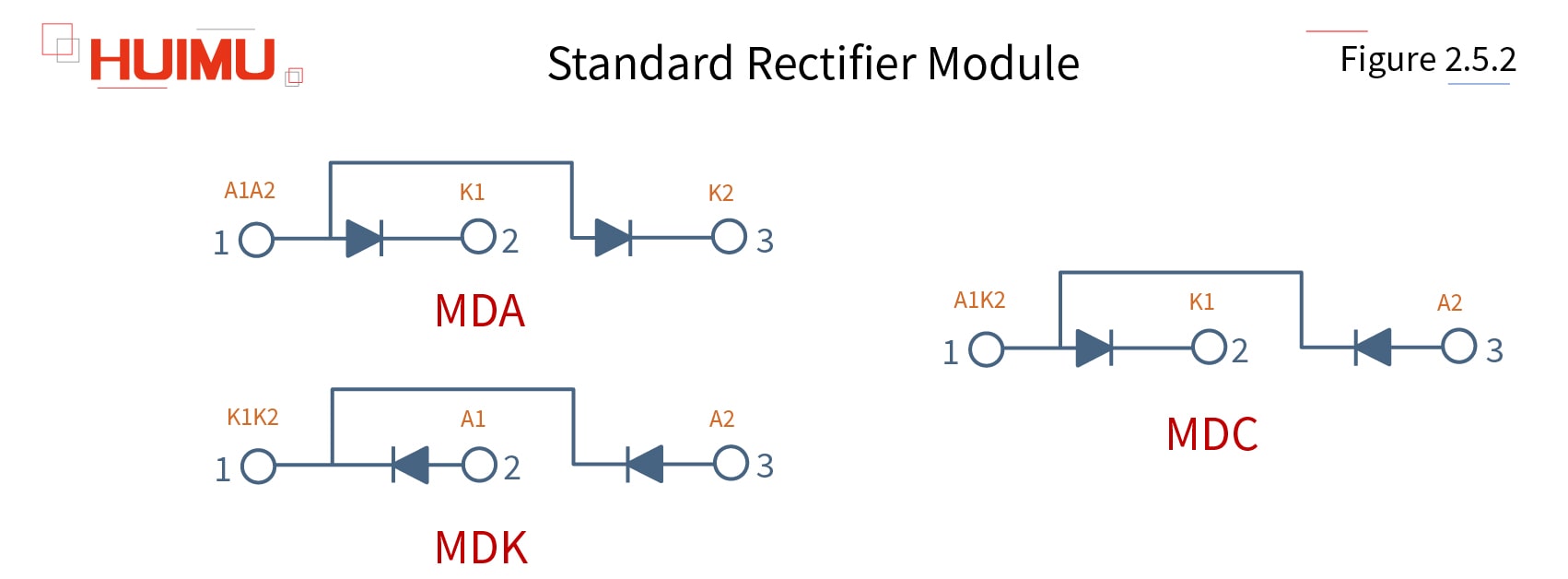

2.5.2) Standard Rectifier Module

MDC, MDA, MDK, MDX Series

The standard rectifier module uses "vacuum + hydrogenation protection" welding technology, which is suitable for the application, such as control system of ac and dc motor, various rectification power supplies, industrial heating control system, lighting system, contactless switch, motor soft start, static var compensator, welding machine, frequency converter, ups power supply, battery charging and discharging and etc.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the rectifier module meet the requirements of the application.

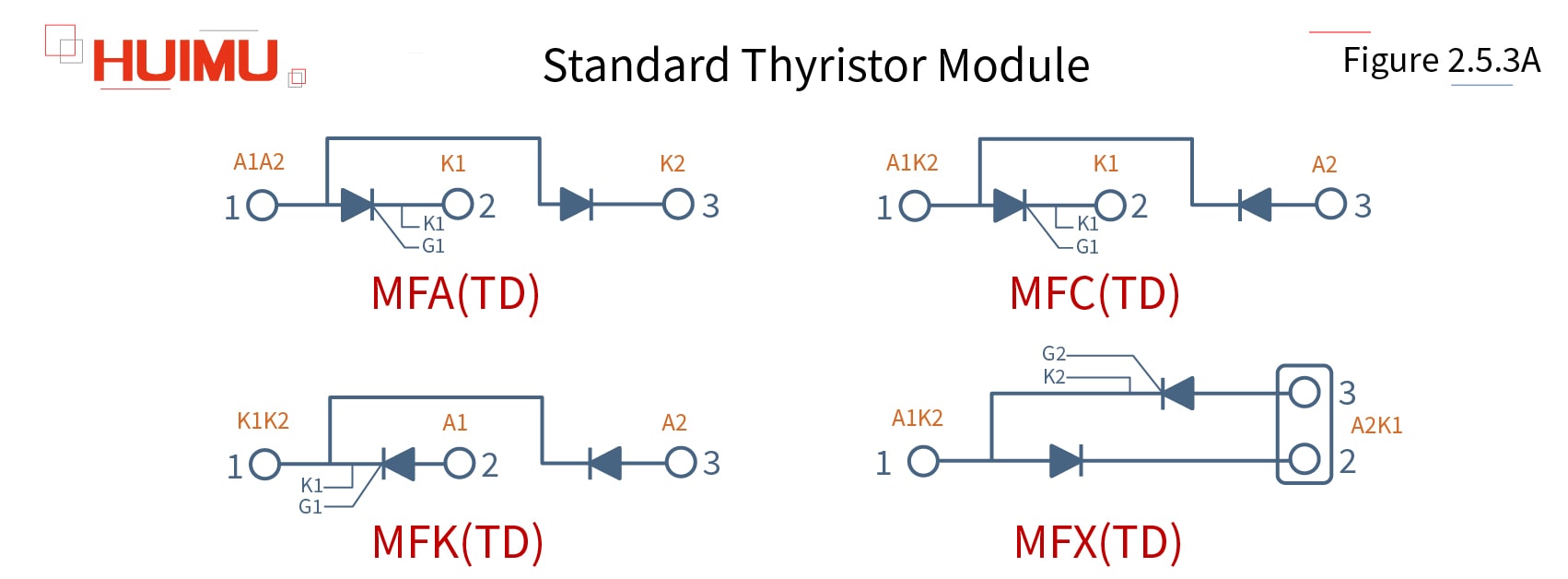

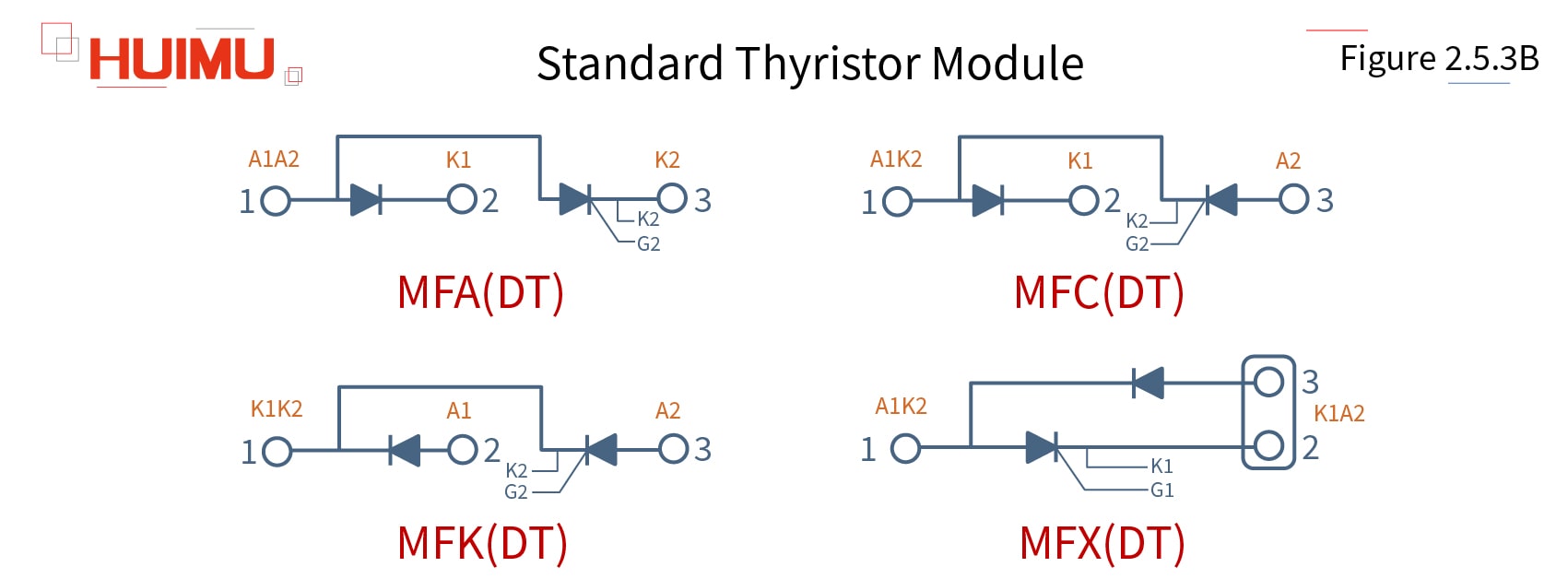

2.5.3) Standard Thyristor-rectifier Hybrid Module

MFC, MFA, MFK, MFX Series

The standard thyristor-rectifier hybrid module uses "vacuum + hydrogenation protection" welding technology, which is suitable for the application, such as control system of ac and dc motor, various rectification power supplies, industrial heating control system, lighting system, contactless switch, motor soft start, static var compensator, welding machine, frequency converter, ups power supply, battery charging and discharging and etc.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the module meet the requirements of the application.

Figure 2.5.3A, MFx(TD) series

Figure 2.5.3B, MFx(DT) series

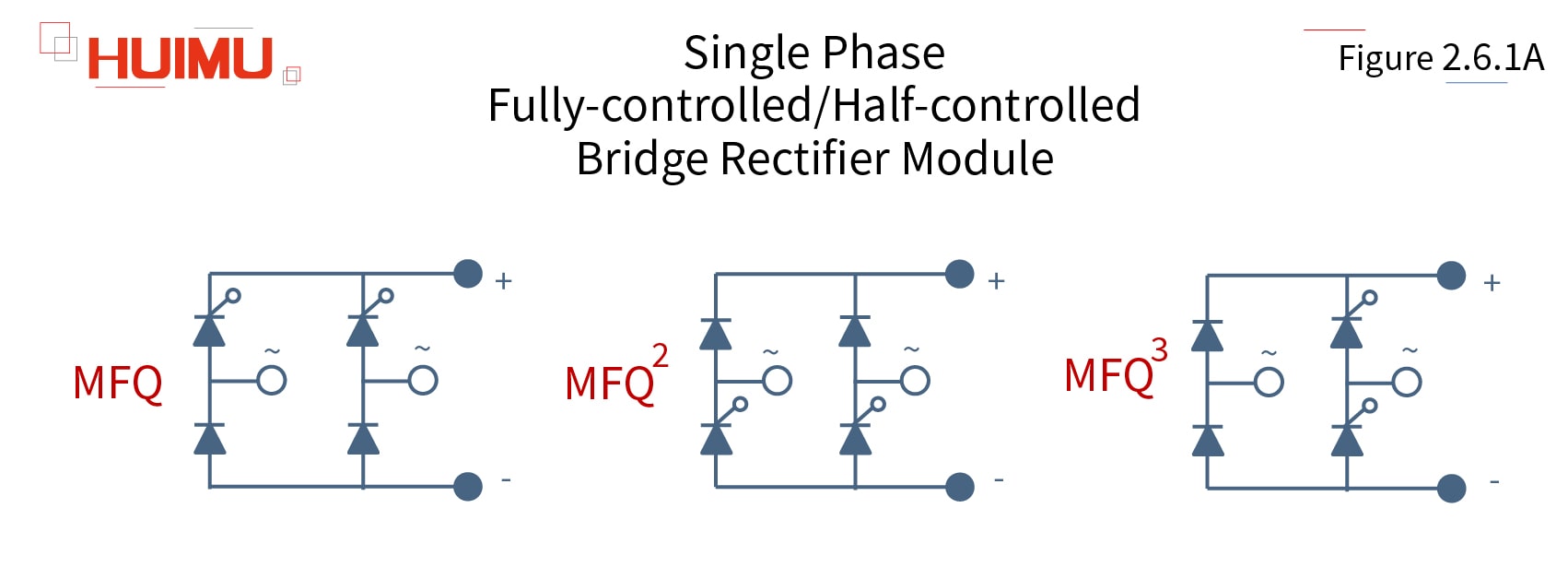

2.6 Fully-Controlled / Half-Controlled Bridge Rectifier Module

2.6.1) Single Phase Fully-controlled / Half-controlled Bridge Rectifier Module

MFQ, MTF, MHF Series

The single phase fully-controlled / half-controlled bridge rectifier module uses "vacuum + hydrogenation protection" welding technology, which is suitable for the application, such as dc power supply of the instruments and equipment, input rectification power supply of the PWM inverter, excitation power supply of the dc motor, input rectification system of switching power supply, soft start capacitor charging system, electrical drive and auxiliary current, inverter welder, dc power charging system and etc.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the module meet the requirements of the application.

Figure 2.6.1A, MFQ series

Figure 2.6.1B, MHF series

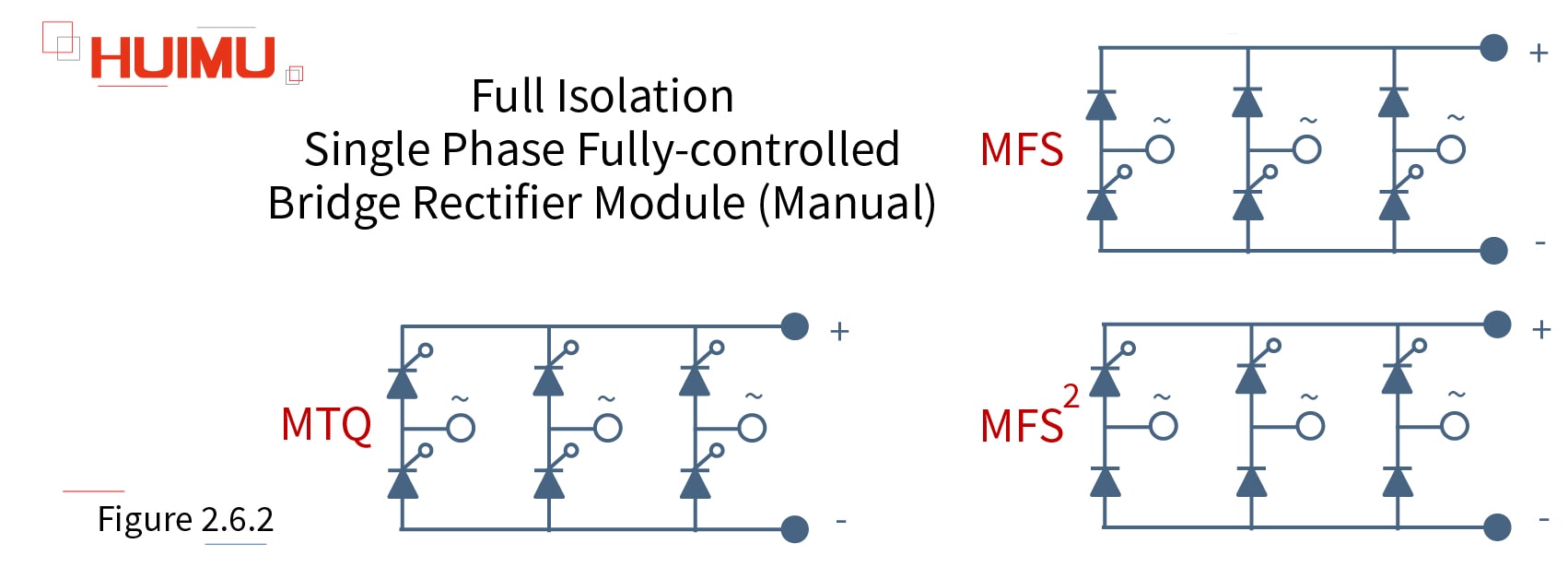

2.6.2) Three Phase Fully-controlled / Half-controlled Bridge Rectifier Module

MTQ, MFS Series

The three phase fully-controlled / half-controlled bridge rectifier module uses "vacuum + hydrogenation protection" welding technology, which is suitable for the application, such as dc power supply of the instruments and equipment, input rectification power supply of the PWM inverter, excitation power supply of the dc motor, input rectification system of switching power supply, soft start capacitor charging system, electrical drive and auxiliary current, inverter welder, dc power charging system and etc.

Note: Before installation and use, please confirm whether the specifications (such as input current, input voltage, output current, output voltage and etc.) of the module meet the requirements of the application.